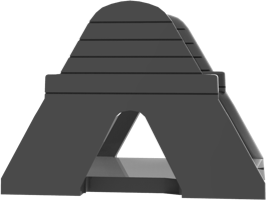

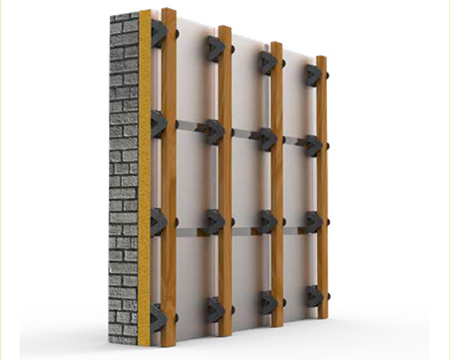

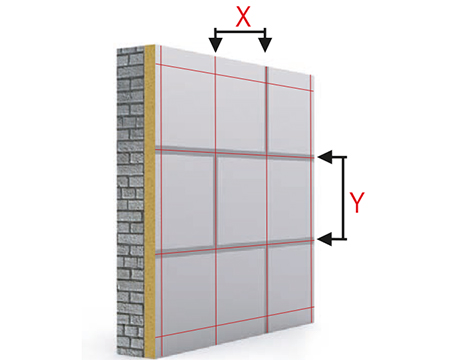

This patented system was designed to create a simple and faster alignment for a supporting structure for any type of cladding that is installed floating with or without insulation.

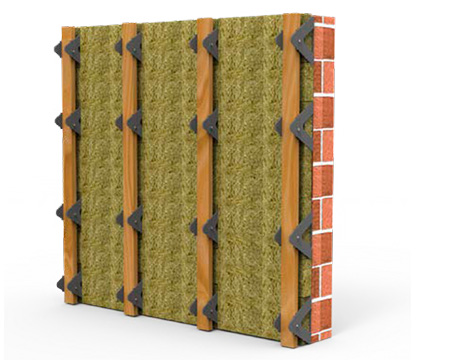

The Gecko® BG210 is ideal for mineral wool applications due to its long range.

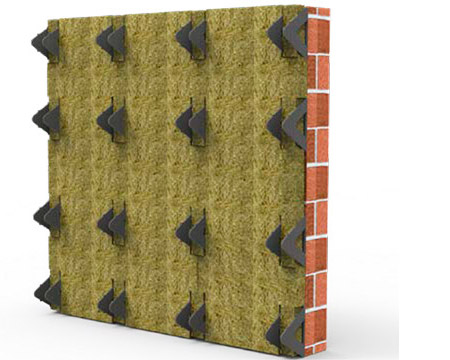

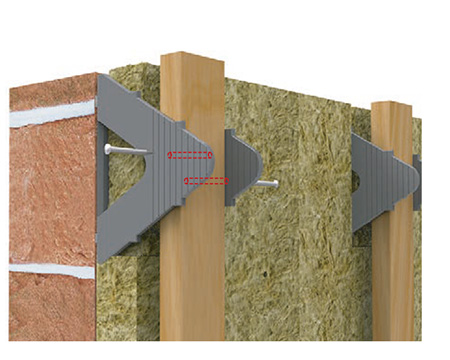

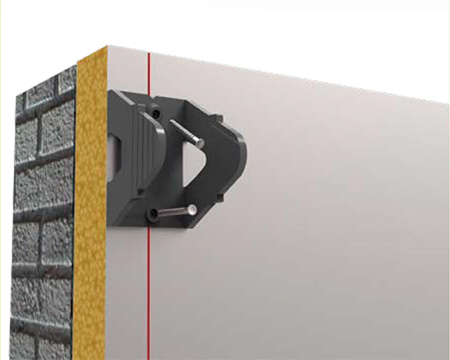

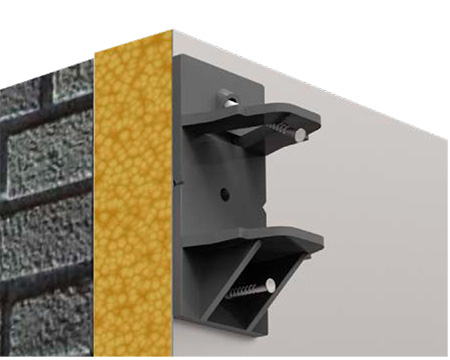

The Gecko® BG210 is mounted directly to the wall or construction behind it. Because the holes are foreseen at 200mm, the fixings (with traditional quick construction) can always be screwed nicely into the mortar joint. Because the insulation comes in and around the bracket, there is no risk of thermal bridges anymore. The Gecko® BG210 has an insulation capacity of120mm up to 210 mm and provides a 90mm alignment capacity.

How do we install the brackets?

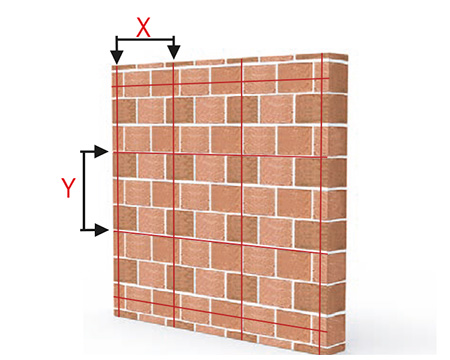

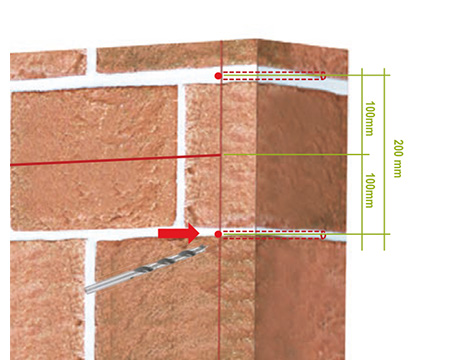

Measure the dimensions on the wall

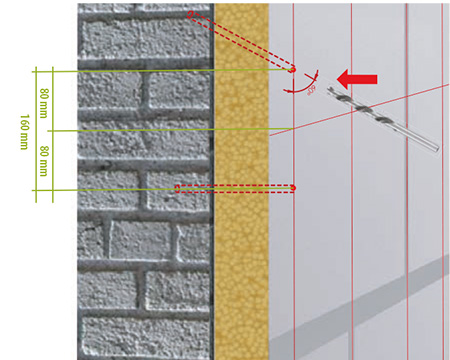

Drill the holes

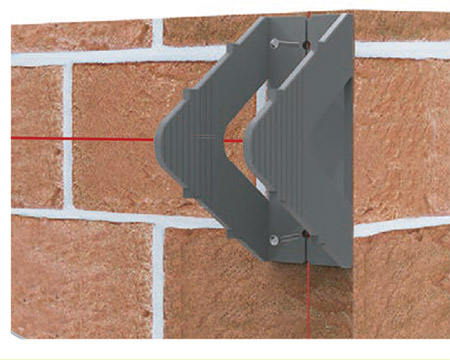

Mount the bracket with screws & plugs

Place the glasswool

Fix the support boards with screws or nail gun

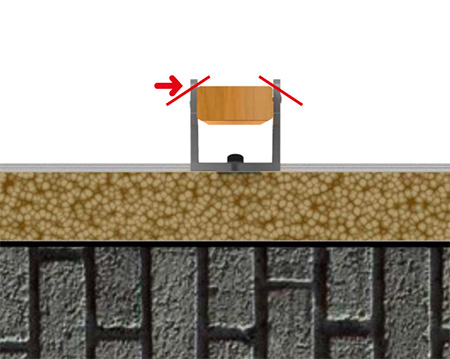

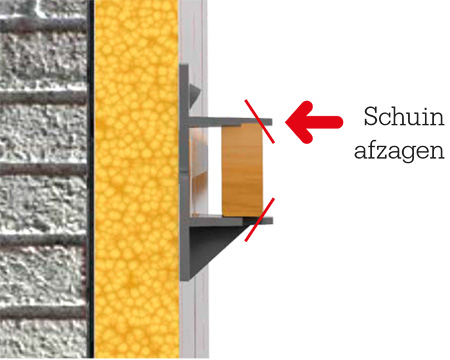

Ready to cut off the protruding parts of the bracket

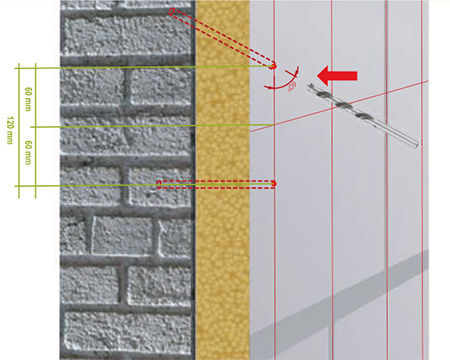

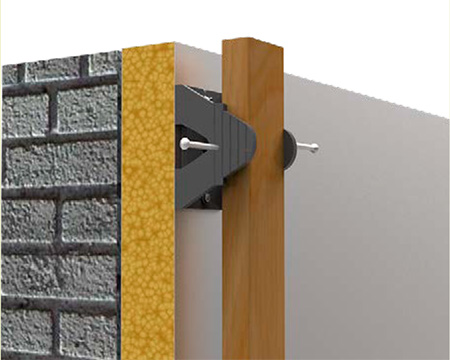

The Gecko® BG90-H and BG110 have been developed for the hard PIR/PUR insulation materials. These brackets are screwed against the insulation whereby the upper facade frame plug is drilled at an angle of 30° and the lower one horizontally into the rearward support wall/construction. They can be used for both insulated and non-insulated facades.

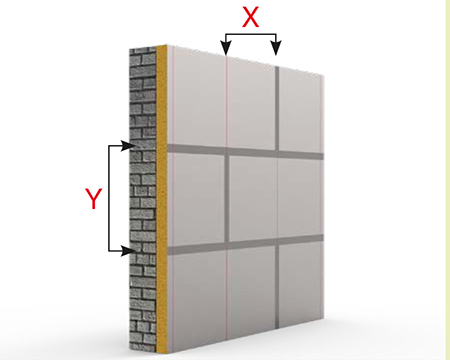

The Gecko® BG110 is the little brother of the BG210. It has a total alignment capacity of 19 to 82mm so that it can compensate for any unevenness in the facade. By lifting the Gecko® BG110 with the bottom corner attachment it is ideal for insulated applications and the holes must be drilled at 120 mm heart to heart. In the case of renovation without insulation, turn the bracket 180° so that it can be fixed with the holes drilled at 60mm heart to heart.

Now available for timber widths of 44mm, 63mm, 89mm and 140mm!

How do we install the brackets?

Place the insulation directly against the wall and measure the dimensions on the insulation

Drill the holes

Mount the bracket with screws

Place the rest of the brackets

Fix the support boards with screws or nail gun

Ready to cut off the protruding parts of the bracket

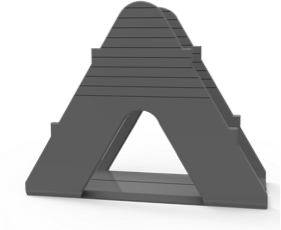

The Gecko® BG90-H is a bracket designed to directly align a horizontal slightly slanted supporting structure without having to provide for double twill work so that a faster assembly can be achieved. This Gecko® BG90-H has an alignment capacity from 9 to 62mm. By lifting the Gecko® BG90-H with the bottom corner attachment it is ideal for insulated applications and holes must be drilled at 160mm heart to heart. In case of renovation without insulation, holes are drilled at 80mm or 160mm heart to heart.

Now available for timber widths of 44mm, 63mm, 89mm!

How do we install the brackets?

Place the insulation directly against the wall and measure the dimensions on the insulation

Drill the holes

Mount the bracket with screws & plugs

Place the rest of the brackets

Fix the support boards with screws or nail gun

Ready to cut off the protruding parts of the bracket

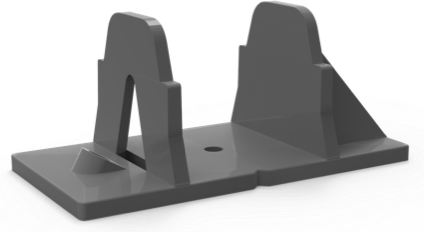

This pin has been developed to enable even faster placement. Thanks to the Gecko® pin you only need to mark off the prescribed centre-to-centre dimensions. You then prick the Gecko® pin through the centre hole of the bracket at the intersection of your lines. Now you can simply drill through the holes of the bracket into the structure behind. The Gecko® pin is the mounting aid that will save you a lot of time.